We will be out in full force at Canada’s largest chemistry conference this year. CSC 2023 is coming to our hometown of Vancouver, and here’s where catch us:

EXHIBITION

Sun, June 4 | 6:30 - 9:00 PM

Mon, June 5 | 9:30 AM - 7:30 PM

Tue, June 6 | 9:30 AM - 7:30 PM

Exhibitor Booth 46

We’ll show you our tech, chat about our capabilities, and offer you a drink ticket to the Organic/Bio & Medchem mixer🍸

A REAL-TIME HPLC REACTION ANALYSIS TOOL

Dr. Lars Yunker, VP Automation and Integration

Mon, June 5 | 9:40 AM

West Meeting Room 115

Symposium: (IN, OR) Innovative Approaches to Mechanistic Analysis

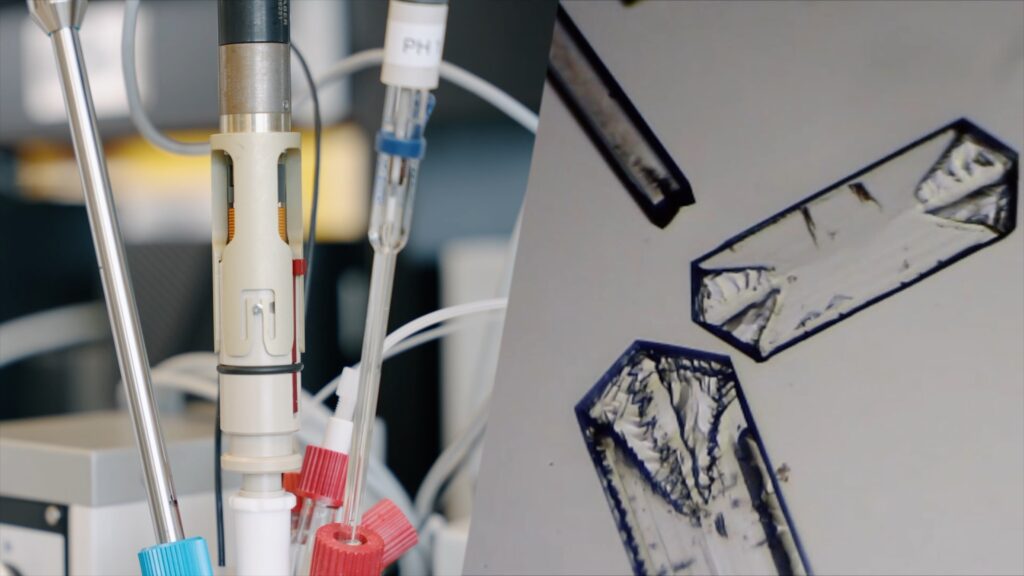

Time-course reaction monitoring is key to understanding which chemical components are involved and what the kinetics of that reaction are. Solutions exist for such monitoring for NMR, IR, MS, and others, but there is no go-to solution for HPLC. HPLC is the gold-standard for quantitative analysis, but analysis of reaction mixtures is complicated by additional sample preparation. It is very challenging to obtain kinetic-quality data as reactions are frequently sampled by hand or age significantly before they are analyzed. Telescope Innovations has developed a platform which directly samples reacting solutions and immediately submits them for analysis on HPLC, yielding dense and high-quality data. This enables quantitation of reaction components as well as kinetic analysis to better understand reactions and inform rational improvements to processes.

TRANSLATING ENABLING TECHNOLOGY FROM ACADEMIA TO INDUSTRY

Shad Grunert, VP Innovation

West Meeting Room 214

Thu, June 8 | 9:25 AM

Symposium: Start-ups and their Successes

Telescope Innovations closes the gap between discovering a valuable chemical and commercially deploying that chemical at scale. The company was born out of Prof. Jason Hein’s academic research group at the University of British Columbia. In academia, we studied a huge variety of chemical systems, from pharmaceutical candidates, to solar cell materials, to organic lasers and critical minerals. But all of these areas presented a recurring challenge: the tools we have to understand how molecules are made are just not insightful or efficient enough. This bottleneck causes a massive delay in deploying crucial materials – materials that are often needed at much faster time scales than they can be prepared. At only under two years of operation, Telescope Innovations has become an industry-trusted partner-of-choice, developing and deploying new enabling technologies to accelerate the deployment of chemicals and pharmaceuticals to the market.

REACTION AUTOMATION TECHNOLOGIES FROM THE PHARMACEUTICAL INDUSTRY ENABLE HIGH PURITY BATTERY MATERIALS

Dr. Ryan Jansonius, Director of Contract Research Services - Chemistry

Thu, June 8 | 5:00 PM

West Meeting Room 217

Symposium: (MT) Advanced Materials in Electrocatalysis, Photocatalysis and Photoelectrocatalysis for Clean Fuel Production

Pharmaceutical- and battery- material supply chains share 3 challenges in common; materials must be supplied in high quantity (>kiloton-scale), with high batch-to-batch consistently, and in high (>99%) purity. Pharmaceutical companies address these challenges using techniques including; in situ reaction monitoring, continuous crystallization, and automated high-throughput experimentation. Incorporating automation and reaction monitoring at the lab scale shortens the timeline to scale up, and reduces uncertainty when the plant is commissioned.

In spite of the advantages, lab-scale process automation is rarely used in the mining industry. Plant designers rely on simple thermodynamic models, and a small number of manually-executed tests to design large-scale plants. Telescope Innovations aims to bridge the gap between these industries by developing lab-scale automation technologies for the mining industry. Our focus is on processes to yield high quality battery raw materials (i.e., lithium, nickel cobalt, and manganese salts) from low quality feed streams and recycled material. In this talk we highlight 3 case studies showing how automation and online analysis enables efficient battery materials manufacturing.